How the Optical Fibre Diameter Analyser Helps in Meeting Stringent Industry Standards

How the Optical Fibre Diameter Analyser Helps in Meeting Stringent Industry Standards

Blog Article

Exactly How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre manufacturing processes stands for a substantial improvement in top quality control approaches. By using real-time, precise measurements of Fibre sizes, this technology attends to the critical requirement for uniformity in production standards.

Significance of Fibre Diameter Measurement

Precise dimension of Fibre Diameter is vital in the area of optical Fibre modern technology, as it straight influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, depletion, and total transmission performance. Accuracy in determining Fibre Diameter guarantees that the optical residential properties are kept within defined resistances, which is essential for optimum signal honesty.

Variants in Fibre Diameter can lead to raised losses as a result of spreading and modal diffusion, affecting the high quality of data transmission. In high-speed communication systems, such discrepancies can cause considerable deterioration of signal quality, resulting in data mistakes and lowered performance. Constant Fibre Diameter is vital for compatibility with connectors and splicing modern technologies, which are important parts of Fibre optic networks.

Quality control processes in Fibre manufacturing heavily depend on exact Diameter measurements to make certain conformity with industry criteria. By carrying out robust dimension techniques, suppliers can improve item dependability, minimize waste, and boost general system performance. Hence, the significance of Fibre Diameter dimension can not be overstated, as it acts as a cornerstone in the innovation of optical Fibre modern technology and its applications in contemporary interaction networks.

How the Analyser Functions

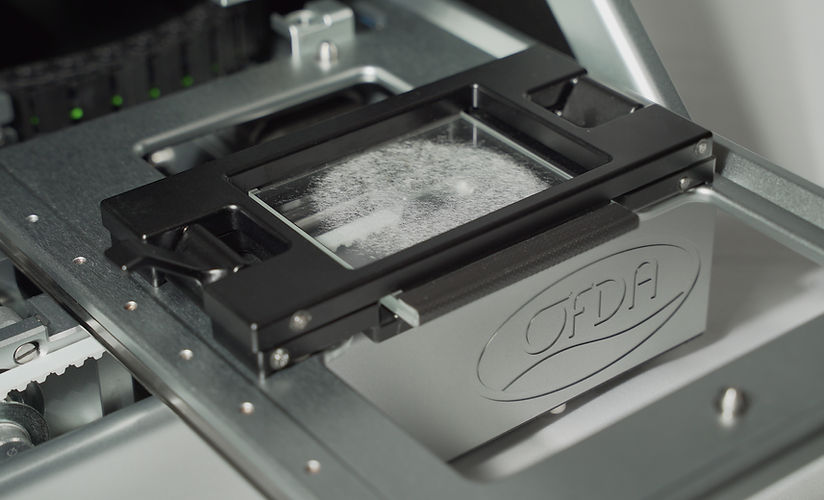

The effective dimension of Fibre Diameter relies on sophisticated analytical strategies that make sure accuracy and reliability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and progressed image processing formulas to properly analyze the Diameter of fibres as they are generated

Initially, a laser beam is guided at the relocating Fibre, creating a cross-sectional shadow. The analyser records this darkness using high-resolution cams placed strategically along the assembly line. The caught photos are after that refined in real-time to determine the Fibre's Diameter with exceptional accuracy.

The system uses advanced formulas that make up numerous factors, including variations in light intensity and environmental conditions, to improve measurement dependability. It can identify minute adjustments in Diameter, such as variations that might occur during the manufacturing process.

In addition, the analyser can handling numerous fibers all at once, increasing throughput without endangering precision. By supplying immediate comments on the Diameter, the Optical Fibre Diameter Analyser plays a vital function in preserving strict quality control criteria, making certain that the last item satisfies industry specifications and consumer needs.

Benefits of Real-Time Monitoring

While traditional approaches of checking Fibre Diameter usually entail lengthy post-production checks, real-time monitoring considerably boosts the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive strategy enables manufacturers to recognize discrepancies in Fibre Diameter as they take place, instead of waiting till production is full to examine quality

By constantly measuring the Diameter during production, manufacturers can make sure that the fibres satisfy stringent specs, leading to minimized variability and enhanced uniformity. Real-time tracking additionally allows prompt corrective activities to be taken, minimizing waste and stopping malfunctioning fibres from getting in the supply chain.

Furthermore, this innovation promotes enhanced information collection and evaluation, providing insights right into manufacturing trends and prospective locations for improvement. Such data-driven decision-making equips suppliers to optimize processes and preserve high criteria of quality assurance.

In addition, real-time tracking cultivates a society of continuous enhancement within the manufacturing setting. Employees are much more engaged when they can see the effect of their job in real-time, resulting in increased responsibility and a dedication to quality. On the whole, the application of real-time tracking systems in optical Fibre production converts to superior product quality and increased customer fulfillment.

Effect On Manufacturing Performance

Applying optical Fibre Diameter analysers dramatically boosts manufacturing performance by you can try here enhancing the production procedure. These gadgets help with constant monitoring of Fibre Diameter, permitting suppliers to identify inconsistencies in real-time. By recognizing variances immediately, production lines can be changed rapidly, minimizing downtime and decreasing the likelihood of producing malfunctioning items.

Additionally, the integration of these analysers right into the manufacturing process enables far better source allotment. With accurate Diameter measurements, drivers can enhance material use, making certain that resources are not wasted on mistaken fibers. This precision additionally adds to much less remodel and scrap, ultimately decreasing production costs.

The automation given by optical Fibre Diameter analysers minimizes reliance on hand-operated evaluations, which are prone and commonly lengthy to human mistake. Because of this, employees can concentrate on more calculated tasks, boosting general performance.

Furthermore, the information generated from these analysers can notify process renovations and facilitate much better decision-making. By analyzing fads in Fibre Diameter variants, makers can implement aggressive steps to boost production strategies and redirected here maintain constant top quality. In summary, optical Fibre Diameter analysers play a critical function in enhancing production performance, resulting in better result and enhanced profitability.

Study and Success Stories

Across different fields, study highlight the transformative influence of optical Fibre Diameter analysers on production procedures. One prominent example is a leading telecoms company that dealt with difficulties with irregular Fibre diameters, resulting in raised rejection rates. By incorporating an optical Fibre Diameter analyser, the company accomplished real-time tracking of Fibre dimensions, leading to a 30% decrease in flaws and substantial cost savings.

In addition, a research study organization focusing on innovative materials made use of optical Fibre Diameter analysers to fine-tune their experimental procedures. The analyser's capability to give detailed understandings right into Fibre consistency enabled the advancement of innovative products with improved efficiency characteristics.

These success tales underscore the crucial function of optical Fibre Diameter analysers in improving quality assurance, enhancing production effectiveness, and driving technology across varied industries.

Final Thought

In verdict, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing quality control within Fibre production. As demonstrated through various case studies, the analyser shows vital for accomplishing remarkable product high quality in Fibre manufacturing.

The implementation of optical Fibre Diameter analysers allowed for rigid high quality control, ensuring that the generated fibres fulfilled exacting market criteria.In final thought, the Optical Fibre Diameter Analyser plays a crucial function in enhancing top quality control within Fibre manufacturing.

Report this page