Custom Membrane Switches for Specialized Applications: A Deep Dive

Custom Membrane Switches for Specialized Applications: A Deep Dive

Blog Article

Discover How Membrane Switches Function and Their Duty in Modern Electronic Devices

Membrane Switches stand for an innovative integration of modern technology and style within the realm of contemporary electronics, functioning as necessary user interfaces in many tools. Consisted of several layers, these buttons make use of pressure-sensitive systems to help with customer communication. Their applications cover various sectors, from customer electronic devices to medical devices, highlighting their adaptability and value. Understanding the ins and outs of Membrane switch performance and their broader effects in enhancing customer experience invites additional exploration right into their layout, benefits, and the ingenious growths shaping their future in innovation.

What Are Membrane Buttons?

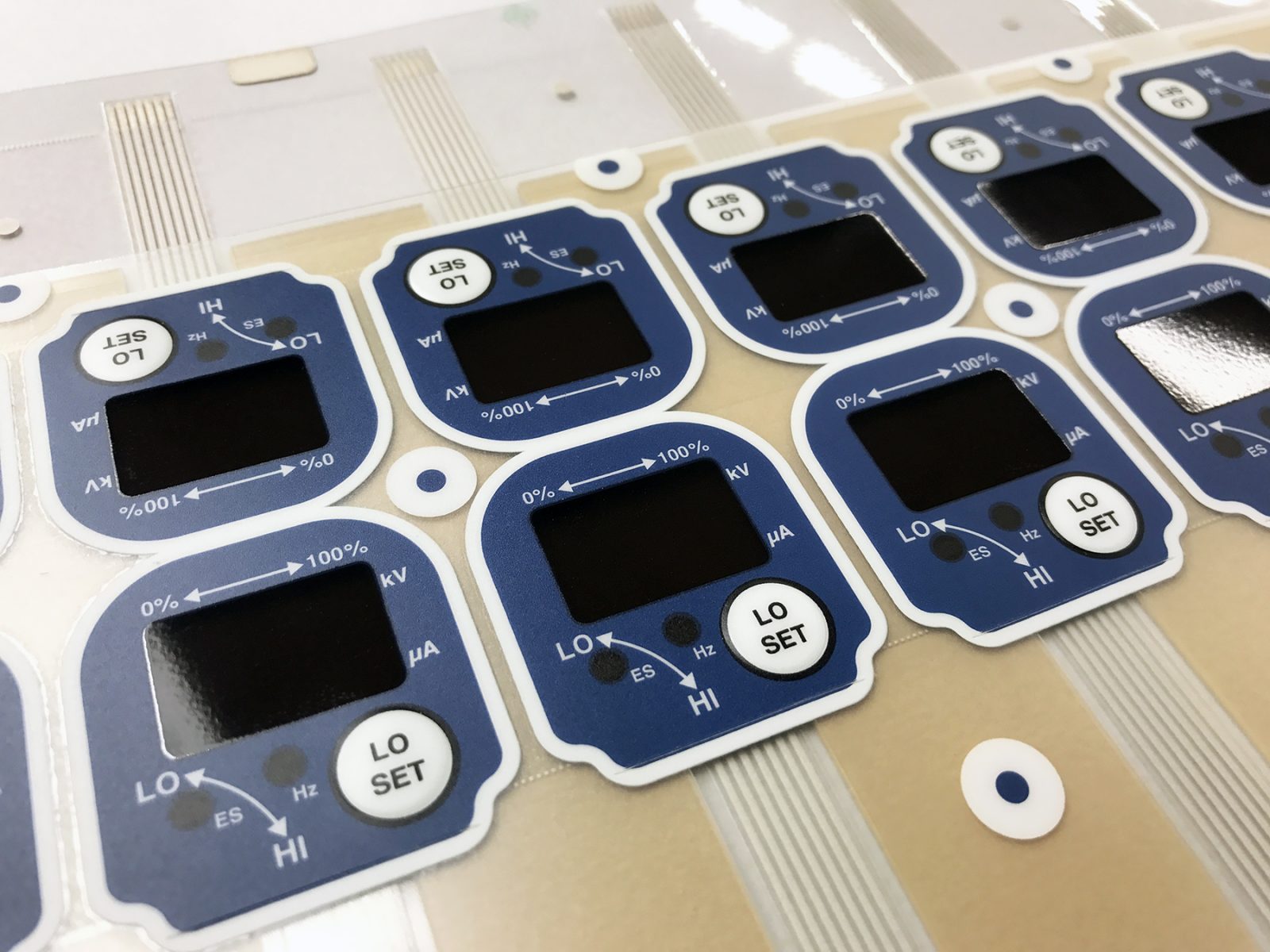

Membrane buttons are differentiated by their longevity and resistance to environmental factors, such as dirt, moisture, and extreme temperatures. They can be customized with numerous graphics, colors, and responsive responses options, improving customer experience while preserving aesthetic appeal - membrane switches. The unification of published circuits enables for seamless assimilation into tools, enhancing overall functionality.

The adaptability of Membrane switches is apparent in their capability to support both easy and intricate control features. They can integrate functions such as LED indicators and touch-sensitive technology, accommodating certain customer demands. As modern technology remains to advance, Membrane Switches continue to be essential for allowing effective and user-friendly individual interfaces, thus playing a pivotal function in the advancement of modern-day electronic tools.

Parts of Membrane Switches

Membrane switches are made up of several vital components that collaborate to produce a reputable and practical interface. The primary components consist of the visuals overlay, adhesive layer, spacer layer, and conductive traces.

The graphic overlay acts as the customer interface, usually printed on an adaptable substrate such as polyester or polycarbonate. This layer not only provides visual allure however additionally consists of tactile comments, visual hints, and protective functions. Below the visuals overlay lies the sticky layer, which secures the switch to the device and guarantees longevity versus ecological tensions.

The spacer layer is crucial for keeping the necessary gap between the visuals overlay and the circuit layer. This void allows for the activation of the switch when pressure is applied. The conductive traces, typically made from silver or carbon, develop the electric paths that finish the circuit when the button is involved.

In addition, a backing layer may be included for structural support and insulation. These components work together perfectly, making certain that Membrane buttons are both resistant and user-friendly, making them indispensable in different modern-day digital applications.

Just How Membrane Switches Job

Exactly how do Membrane Switches function effectively within electronic tools? Membrane Switches operate the principles of pressure-sensitive technology, using a layered construction that consists of visuals overlays, adhesive layers, and conductive aspects. When an individual uses stress to the switch, the leading layer warps, enabling the conductive aspects underneath to make get in touch with and complete an electric circuit. This action sets off the wanted feature within the gadget.

The design of Membrane buttons is critical for their reliable operation (membrane switches). The layers are thoroughly crafted to provide responsive responses, durability, and resistance to environmental factors such as dampness and dust. The addition of domes-- tiny, raised locations within the switch-- boosts tactile feedback, supplying customers with an obvious click experience upon activation

In addition, Membrane switches can be personalized in regards to size, form, and graphics, making them ideal for numerous applications. They are frequently used in control panels, medical devices, and consumer electronics due to their streamlined layout and reliability. On the whole, the efficient performance of Membrane buttons is pivotal in boosting customer communication and making certain seamless operation in contemporary digital devices.

Applications in Modern Devices

Using their one-of-a-kind style and functionality, Membrane buttons have ended up being important parts in a vast array of contemporary electronic gadgets. These versatile interfaces are employed in customer electronics, commercial tools, clinical tools, and vehicle controls, supplying seamless user interaction.

In consumer electronic devices, Membrane buttons are commonly discovered in home appliances like microwaves, washing devices, and various other house devices, where they allow intuitive control with view a smooth account. Their low-profile style assists in integration right into compact devices, improving visual appeal without jeopardizing functionality.

In industrial applications, Membrane Switches offer as control board for machinery, providing toughness and resistance to severe atmospheres. Their capacity to hold up against dampness and impurities makes them excellent for use in production and processing markets.

Medical devices also take advantage of Membrane switches, which are developed to be easy to tidy and keep, ensuring health in professional settings. They are typically utilized in diagnostic equipment, client monitoring systems, and mobile medical tools, where reliability is extremely important.

Advantages of Membrane Switches

One of the vital advantages of Membrane switches is their convenience, which permits them to be tailored for a variety of applications across several industries. These buttons can be designed in different sizes and shapes, fitting one-of-a-kind item needs while offering smooth combination into tools. Their slim profile makes it possible for a small and streamlined style, usually boosting the visual allure of electronic items.

One more considerable benefit is their durability - membrane switches. Membrane switches are normally immune to dirt, moisture, and chemicals, making them excellent for harsh environments. This durability prolongs their lifespan contrasted to standard mechanical buttons, reducing the requirement for regular replacements

In addition, Membrane Switches deal cost-effectiveness. The manufacturing process includes printing innovations that minimize manufacturing expenses, specifically for huge runs. This cost, combined with low maintenance needs, makes them an appealing choice for producers.

Conclusion

In conclusion, Membrane Switches stand for a significant advancement in customer interface modern technology within modern-day electronics. Their layered construction, pressure-sensitive operation, and adaptability to various applications emphasize their relevance across several industries. The resilience and environmental resistance of visit this page Membrane Switches further improve their allure, making them a favored option for manufacturers seeking adjustable and trustworthy options. As the need for instinctive and durable user interfaces remains to expand, the function of Membrane switches fit customer experience will undoubtedly increase.

Membrane Switches represent an advanced integration of innovation and design within the world of modern-day electronics, serving as important user interfaces in numerous devices.In the realm of modern-day electronics, Membrane Switches serve as important components that promote individual communication with devices. As modern technology proceeds to advance, Membrane Switches stay important for enabling intuitive and efficient user interfaces, thus playing a pivotal function in the improvement of modern electronic gadgets.

Just how do Membrane Switches function efficiently within electronic devices? In general, the effective functioning of Membrane switches is critical see here in boosting customer communication and making certain seamless procedure in modern-day digital gadgets.

Report this page